August 2019

Fiber enthusiasts often become tool enthusiasts. It doesn’t happen overnight, however. I had only one pair of knitting needles for decades. I still have them. Susan Bates straight needles in a US size 8.  They are pink and were given to me by a neighbor who taught me to knit when I was in grade school. When I returned to knitting in the late 80s and early 90s, I complained about buying two sets of needles for one project. At that point I was buying the least expensive bamboo needles. Budget was always an issue in those days and the cost of needles was something to consider, especially given the cost of yarn, parking, housing, child care …

They are pink and were given to me by a neighbor who taught me to knit when I was in grade school. When I returned to knitting in the late 80s and early 90s, I complained about buying two sets of needles for one project. At that point I was buying the least expensive bamboo needles. Budget was always an issue in those days and the cost of needles was something to consider, especially given the cost of yarn, parking, housing, child care …

Fortunately, budgetary constraints are not what they once were, I now know much more about knitting needles, and I recognize the value of good tools. Unfortunately, the tendency to start new knitting projects before finishing old ones has prevailed and led to the acquisition of many knitting needles.  Also unfortunately, the concept of a needle exchange program has never appealed to LYS owners. I really think this is something to explore! If there ever is a needle exchange, you will not find my Signature Needle Arts double pointed stiletto needles.

Also unfortunately, the concept of a needle exchange program has never appealed to LYS owners. I really think this is something to explore! If there ever is a needle exchange, you will not find my Signature Needle Arts double pointed stiletto needles.  The offspring once needing child care are now wonderful adults who gifted me with a range of these double point needles over a couple of years. I’ll not be parting with these fine tools, thank you very much!

The offspring once needing child care are now wonderful adults who gifted me with a range of these double point needles over a couple of years. I’ll not be parting with these fine tools, thank you very much!

I never had much of a relationship with household tools until I owned my own home and was a single parent. Then it became important to have basic tools like a hand-held drill, hammer, screw drivers, nuts and bolts, plyers, level, and measuring tape. I was a bit excited about a stud finder – the kind that finds studs in walls, not dating sites. But such tools were just part of the garage or basement, depending on where I lived, and came out to play only when needed. In the meantime, I acquired a number of fiber arts tools: spinning wheel and all that goes with that, hand cards, drum carder, wool combs, and materials for dyeing. That all seemed fairly manageable and did not require much in the way of fixing, trouble shooting, or any other DIY-type of efforts. The biggest problem with all these tools is the real estate to house them.

When my now husband moved in with me and my kids, he brought along his tools and when we bought a house together, my tools suddenly disappeared. The challenge of finding a screwdriver or plyers did not escape my notice, but he usually was able to offer what I needed. I didn’t think much about it until I had my first loom, a four-shaft counterbalance, and went looking for my level. I realized I had not seen any of my tools in several years and they were nowhere to be found. Not only that, but I couldn’t find any of his tools, either.

DH (Dear Husband in Ravelry speak) is a very busy man and has his own way of organizing his things. By this number of years in our shared home, his organization schema for things in the garage, where tools are kept, was approaching what I call chaos. So, I did what any independent and pragmatic fiber lover would do. I purchased a new set of tools and tool box and pronounced them OFF LIMITS.  I keep them in my fiber closet. DH is required to sign a contract before he borrows anything. We joke about it, but he also knows I am dead serious about it. And he never goes to get a tool without asking.

I keep them in my fiber closet. DH is required to sign a contract before he borrows anything. We joke about it, but he also knows I am dead serious about it. And he never goes to get a tool without asking.

As a weaver, tools took on a new importance to me. Looms sometimes need fixing and adjusting and some maintenance is required. I like to think I take care of my looms. They get preventive maintenance at least once a year and I regularly remove lint build up, check them over between projects, and adjust whatever needs adjusting. Ok, I talk to them, too. Nicely. I appreciate these fine tools.

Of course, along with weaving comes a need for ever more tools, such as bobbin winders, bobbins, shuttles, temples, warping boards and mills, cone holders, warping sticks or paper, reeds, reed holders, reed hooks . . . the list goes on. Recently, I had the opportunity to put my original knitting needles to work on a weaving project. I used them to make a spool rack for winding bobbins with linen. It actually did result in less twist going into the linen as I wound the bobbins.

It actually did result in less twist going into the linen as I wound the bobbins.

As a knitter, I have been combining old and new technology for a number of years. Knitting is an ancient art and important means of making clothing. Today we have coated extra sharp circular needles made of materials never dreamed of by the hardworking islanders who knitted Aran sweaters to keep their fishermen warm. And while I’m knitting one of those sweaters today, I’m using technology in the shape of a digital database (Ravelry) and an ingenious app (KnitCompanion). As a beginning backstrap and Baltic band  weaver, I’m using the ancient technique of backstrap weaving with my iPad and two apps: PatternGenius to create a chart and KnitCompanion to display that chart and track my progress with the pattern. I couldn’t be happier!

weaver, I’m using the ancient technique of backstrap weaving with my iPad and two apps: PatternGenius to create a chart and KnitCompanion to display that chart and track my progress with the pattern. I couldn’t be happier!

Loom weaving is an age-old art, too. And today weavers are combining new technology with the creation of cloth. One look at the plastic box on the castle of my Mighty Wolf loom and you know this is true because such materials are relatively recent. (Of course, a jack loom is also a recent invention!) This plastic box would be the brain for my Tempo Treadle (TT).  I’m surprised more weavers don’t know about this amazing tool! Strong magnets are attached to the bottom of each treadle. Below the treadles is a sensor array that senses the proximity of the magnet when a treadle is pressed. By way of a ribbon of wires connecting the sensor array to the CPU or brain, this sends a signal. The draft, in the form of a Weaving Information File (wif), is copied from a computer with weaving software to a micro SD card that is inserted into the CPU. So, when an incorrect treadle is pressed, as happens often in my many treadling errors, a tone (I have it set to a loud bleep) is emitted, announcing that I’ve pressed the incorrect treadle. For someone who always moved left when the yoga teacher said right, this is a miracle! It is a gift to be immediately informed you are about to make an error that you otherwise may not see for a few inches. If only I could calculate the amount of time, energy, and materials this has saved I could say that TT has paid for itself! TT performs many other functions, but this describes why I most love this little tool.

I’m surprised more weavers don’t know about this amazing tool! Strong magnets are attached to the bottom of each treadle. Below the treadles is a sensor array that senses the proximity of the magnet when a treadle is pressed. By way of a ribbon of wires connecting the sensor array to the CPU or brain, this sends a signal. The draft, in the form of a Weaving Information File (wif), is copied from a computer with weaving software to a micro SD card that is inserted into the CPU. So, when an incorrect treadle is pressed, as happens often in my many treadling errors, a tone (I have it set to a loud bleep) is emitted, announcing that I’ve pressed the incorrect treadle. For someone who always moved left when the yoga teacher said right, this is a miracle! It is a gift to be immediately informed you are about to make an error that you otherwise may not see for a few inches. If only I could calculate the amount of time, energy, and materials this has saved I could say that TT has paid for itself! TT performs many other functions, but this describes why I most love this little tool.

At Convergence 2018 I had the good fortune to meet one of the makers of TT, ![]() Dawne Wimbrow. Barry Duncan is the other maker. Each device is built upon ordering and a 3-D printer is involved. There is definitely software and hardware development involved, each device is built to the specifications of the type of loom being used, and TT is not available for every type of loom. One thing I can say for certain is that Dawne and Barry offer the very best customer service. I can send a question or problem via email on a Sunday evening and have an answer from one or both within minutes. They are thoughtful and helpful, problem solving whatever issues or questions I have had and to date, the issues have always been operator error. Well, there is a learning curve.

Dawne Wimbrow. Barry Duncan is the other maker. Each device is built upon ordering and a 3-D printer is involved. There is definitely software and hardware development involved, each device is built to the specifications of the type of loom being used, and TT is not available for every type of loom. One thing I can say for certain is that Dawne and Barry offer the very best customer service. I can send a question or problem via email on a Sunday evening and have an answer from one or both within minutes. They are thoughtful and helpful, problem solving whatever issues or questions I have had and to date, the issues have always been operator error. Well, there is a learning curve.

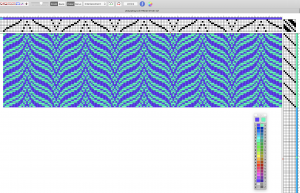

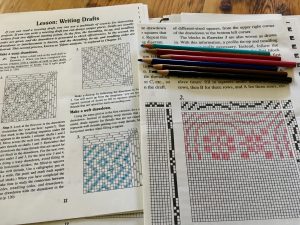

It must be said, however, that to use TT, one needs weaving software. And to use weaving software, one needs a reliable computer.  More tools. More to learn, more to do, and more assistance provided. I resisted weaving software for the first few years . . . and then I gave in. I am learning as I go but already, I see advantages over pencil and paper. As much as I loved studying Madelyn Van der Hoogt’s Complete Book of Drafting,

More tools. More to learn, more to do, and more assistance provided. I resisted weaving software for the first few years . . . and then I gave in. I am learning as I go but already, I see advantages over pencil and paper. As much as I loved studying Madelyn Van der Hoogt’s Complete Book of Drafting,  and I truly did enjoy it, I disagree with those who say that weaving software takes away from learning weave structure. With software I’m not coloring in each square on graph paper, but I can learn plenty about a drawdown and I can also learn how to manipulate a draft and see the results fairly instantaneously. I have miles to go in this department and, in the meantime, I’m having an awfully good time of enjoying my tools.

and I truly did enjoy it, I disagree with those who say that weaving software takes away from learning weave structure. With software I’m not coloring in each square on graph paper, but I can learn plenty about a drawdown and I can also learn how to manipulate a draft and see the results fairly instantaneously. I have miles to go in this department and, in the meantime, I’m having an awfully good time of enjoying my tools.

While I have great appreciation for a number of these tools, there is one tool that is near and dear to my heart. This tool, the single tool that prompted me to write about tools, is likely nearing 100 years old. I use a cloth measuring tape that may have been my grandmother’s.  It was definitely my mother’s and I believe it had been her mother’s before. I found it in the round thread and button tin with the darning thread and the sock darning egg that had been my grandmother’s. In fact, that round tin was my grandmother’s, too. Recently I developed a nostalgic appreciation for the tape measure that is so often pinned to the new cloth I am weaving.

It was definitely my mother’s and I believe it had been her mother’s before. I found it in the round thread and button tin with the darning thread and the sock darning egg that had been my grandmother’s. In fact, that round tin was my grandmother’s, too. Recently I developed a nostalgic appreciation for the tape measure that is so often pinned to the new cloth I am weaving.

The nostalgia is illogical. No family member I know of was a weaver or knitter and such handcrafts were not valued when I was growing up. In fact, I don’t know when my mother would have ever used the tape measure. But it represents a point of connection with a past that was lost.

No one in the family ever discussed all the emigration that took place and I have only recently pieced that together with current day research. My grandparents, all the first generation to be born in this country, died before I was born. My parents are now many decades deceased.

No doubt somewhere in my family tree, on a different continent, someone in my family created some type of cloth, either knitted or woven, and more certainly, someone took needle and thread to cloth. Now I am the individual spinning, knitting, and weaving and taking needle and thread to my woven cloth. Some of that cloth is given to my adult offspring and so it goes forward.

And so, when I look at the old cloth tape measure on my newly woven fabric, I am looking at much more than a simple tape measure. Even if cloth tape measures were more available today (and many of us do wish that), I am looking at so much more. It is something I feel in my heart and it fills me in a lovely way when I weave. I think I can best sum up that heart feeling as gratitude and appreciation. That would be for the past, distant and not so distant, and also very much for the present.

And so, when I look at the old cloth tape measure on my newly woven fabric, I am looking at much more than a simple tape measure. Even if cloth tape measures were more available today (and many of us do wish that), I am looking at so much more. It is something I feel in my heart and it fills me in a lovely way when I weave. I think I can best sum up that heart feeling as gratitude and appreciation. That would be for the past, distant and not so distant, and also very much for the present.

♣